Manufacturing

Case Farms

Dudley, North Carolina

Project details

Case Farms has been producing high-quality chicken products since 1986. To meet the Southeast’s growing demand for responsibly raised poultry, Case Farms chose to expand one of its existing processing facilities in Dudley, NC.

This project included two phases that took place simultaneously.

Phase 1:

- 8,000 SF -33° VRT

- 16,000 SF access corridor

- 20,000 SF palletizing area

Phase 2:

- 50,000 SF -10° storage freezer

- 62,000 SF supporting office

- Dock and additional support spaces

Case Farms’ original process required product to be transported off site and frozen in a blast freezer. This process strained goals for quality and product loss. It also required significant human interaction (14 touches).

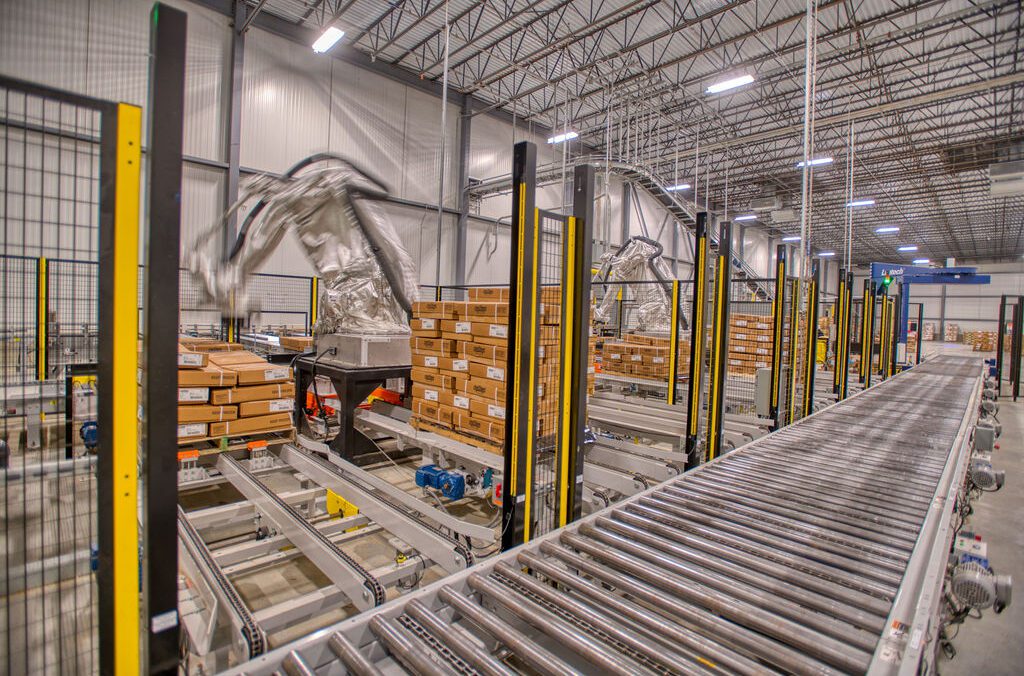

Primus’ in-house automation division developed a more efficient material flow plan that included the following steps:

- Product is delivered directly to the VRT via conveyor

- Product is blast frozen in the VRT

- Product is moved via conveyor to the robot palletizer

- Product is wrapped

- Product is moved via forklift to the freezer warehouse

This new, innovative approach moves product through the facility faster, safer, reduces energy and reduces cost.

Primus completed the construction phase with zero interruptions to ongoing activities. One of the innovative solutions the Primus design team implemented to achieve this was Point Cloud. A scan of the existing facility was uploaded to Revit and used to accurately portray existing conditions. Conveyance and other equipment was imported into the model and could be checked for interferences before construction began.